Details

Thermal drift is a phenomenon where changes in temperature affect the performance and accuracy of electronic and mechanical systems. It is particularly important in precision measurement devices, where temperature variants can introduce errors.

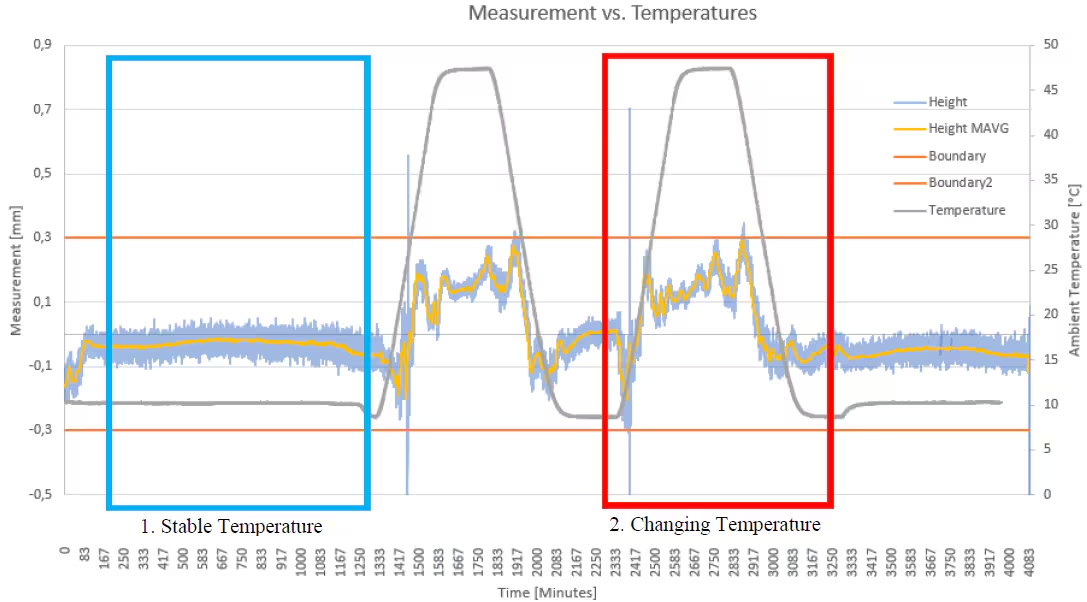

L38 is also affected by temperature within a certain range. The following figure shows the impact of changes in the ambient temperature for L38-500. As you can see, within the stable temperature region (approximately maintains at 11°C), the measurement drift is less than the +/- 0.1mm, while in the changing temperature region, the measurement drift is increased to +/- 0.3mm. (L38 is calibrated to an ambient temperature of 21°C.)

L38-500's measurement drift with respect to the change of ambient temperature.

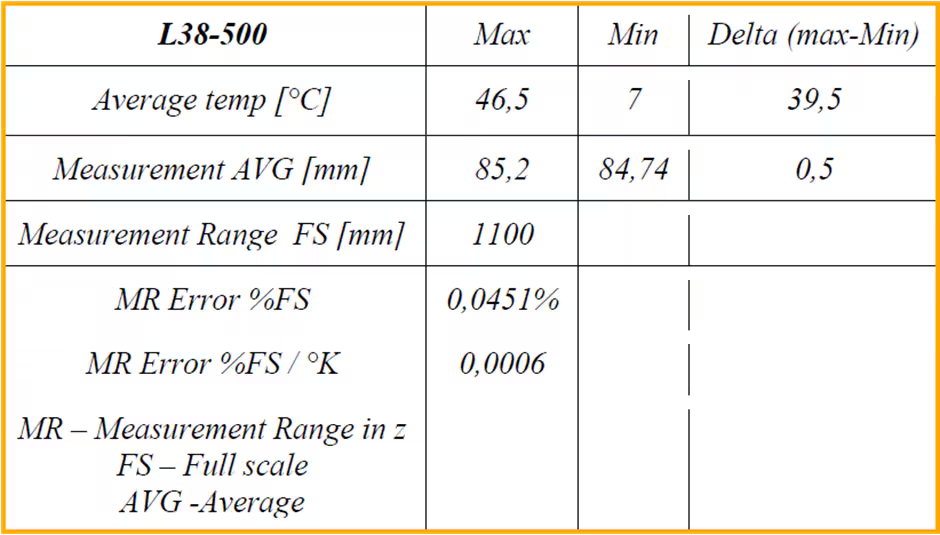

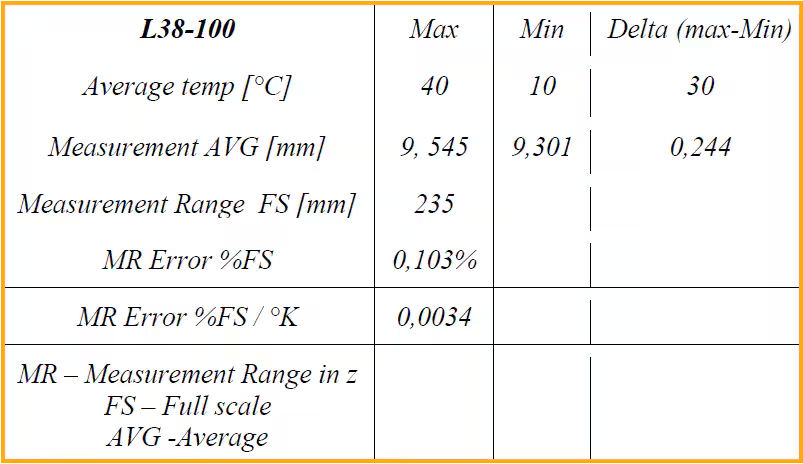

Here are more detailed test results within the changing temperature region for L38-500 and L38-100 respectively:

L38-500's characteristics within the changing temperature region.

L38-100's characteristics within the changing temperature region

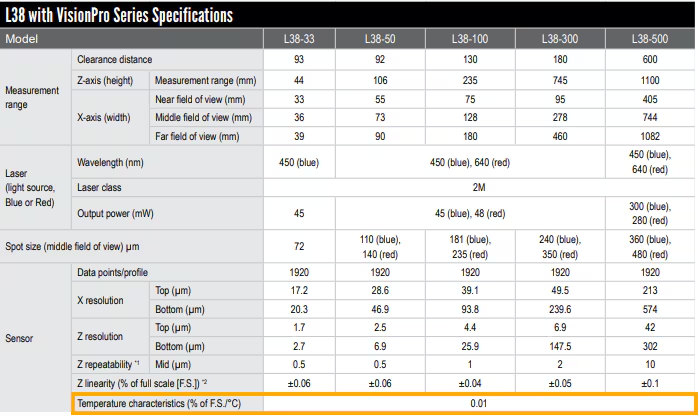

As you can see, the Measurement Range Error of Full Scale per degree (MR Error %PS /°K) of L38-500 and L38-100 are 0.0006 and 0.0034 respectively, which are both less than the upper limit (0.01) of the temperature characteristics in our L38 Specification shown below:

Thus, both L38-500’s and L38-100’s performance in measurement accuracy against the changing temperature satisfies the temperature characteristics shown in specification. To completely remove the impact from temperature is unrealistic in real applications, but for minimizing the thermal impact on measurement error, the following guidelines should be followed:

- Keep thermal load constant within the specified temperature thresholds.

- High or low is acceptable, but fluctuation in excess of 10°C/h is not.

- The connection to the machinery surrounding the sensor should function as a heat sink, or at the very least, it must not contribute to the thermal load.

- The camera mounting plate should be connected to a metal plate.

- Take temperature readings when in doubt, wait for a stabilization of the temperature reading over time. Use thresholds appropriate for the applications accuracy requirements.

- Ensure ideal airflow of 0.05m/sec.

- Sensor mounting solutions should never obstruct airflow through the cooling ridges on the back.

- An ideal connector for the sensor is crafted from aluminium.

- Averaging measurement results leads to an overall more accurate and stable outcome.